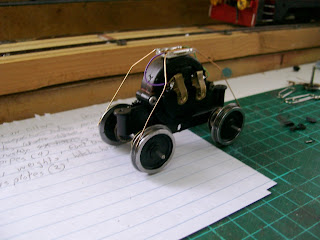

These part built models were returned to me recently. These were started some time back and given to a friend when I was more involved in S scale. The recipient now has more than enough kits to keep him busy so presented them back. Thus, I have continued on with their construction. The CV is built of styrene and the S wagon from some offcuts of ply out of a skip with card, pop stick and paper details. No interior detail and top lips as it is to be tarped. So far I have added the strapping to the side of the S and the roof to the CV. Solebars, W irons, wheels and couplers were next. Both are mounted on GME W irons with a mixture of Slaters and Peco wheels.

Sometimes things happen we are not aware of. The S wagon was placed in the window sill while the epoxied W irons were left to set in a spacing jig. It seems when I drew the curtains shortly after, I brushed against them skewing the setting. So I now have a crabbing S wagon. Fortunately the vertical alignment remained in place and it doesn't rock when placed on a flat surface. A job for another day...... cost of each of these wagons will be less than $40.